Challenge / Situation

Meyer Blechtechnik AG, which specialises in sheet metal processing, was looking for an individual silo technology solution for a customer. When building metal silos with heights of up to 18 m and a total weight of up to 40 t, the company was looking for a solution that would make the use of cranes superfluous. The silo rings needed to be able to be inserted and screwed from below – a process that requires the highest degree of precision and safety. The stroke had to be absolutely synchronous and could not be lowered at any time without control. In addition, the device had to be robust and reliable for outdoor use.

strong>Solution

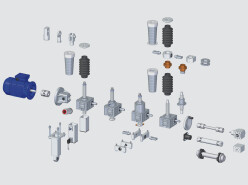

Together with the customer, the appropriate design was defined step by step in the Nozag NSE configurator. The calculation showed that 15 NSE50-RN screw jacks in rotating design, which were connected to each other via cardan shafts, were to be used. This configuration ensures the synchronous stroke of all elements and also offers reserves against buckling or unbalanced loads, such as can be caused by wind. The solution is low-maintenance and designed for easy operation, guaranteeing permanently safe operation. The Nozag modular spindle lifting gear system has also proven itself in this project: no special parts were required and delivery was possible within a very short timeframe.

«The successful consultation on the necessary components was carried out in a structured manner with the Nozag NSE configurator and in a personal consultation.»

Statement from a satisfied Mr Obi from Meyer Blechtechnik AG

Products / Detailed information

Nozag's modular system was also very helpful here. It's also a perfect example of how the online configurator for screw jacks can be used to provide support, and also by the customer themselves. Try our configurator yourself or let us advise you.

Shop

Shop

Any Questions?

Any Questions? Please call us

Please call us Products search

Products search

Shop

Shop