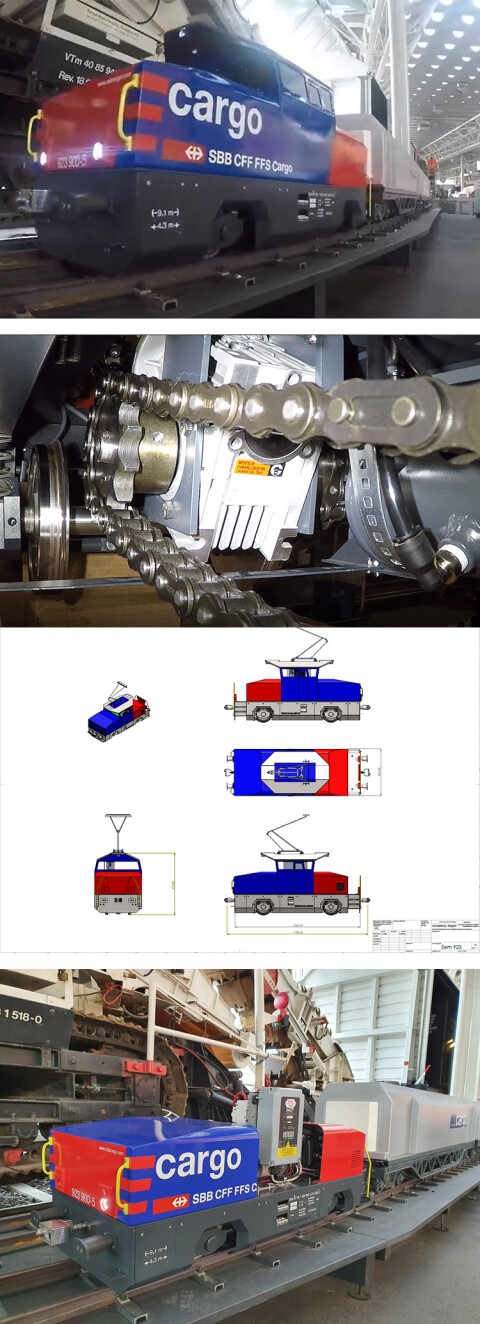

A model marshaling yard with a Eem 923 900-5 locomotive and refrigerator cars was created for the Swiss Museum of Transport and SBB Cargo. The model locomotive was built at a 1:8 scale and offered very little space for the required drive. It needed a very compact drive technology that nevertheless allowed a very fine control. The exhibition was placed under the motto “Experience logistics” with a strong focus on the marshaling and “coupling of wagons”.

- Compact construction

- Fine transmission ratio

Resolution / The way forward

The drive technology possible for the locomotive was very quickly determined - it had to be a worm gear. It allowed the uniform transmission of the propulsive power on both axes by means of chain sprockets and roller chains. The compact design of the very small-dimension worm gear CM040-01 allowed installing it in the locomotive. Its transmission ratio of 1:10 ensured a very accurate adjustment of the travel speed, in particular for the slow motion when coupling the wagons. Nozag accompanied the development from the first consultation up to the delivery, using a standard product subsequently adapted for the needs and delivered ready for installation.

- Compact worm gear CM040

- Transmission ratio 1:10

- Chain sprockets and chains for the axis drive

«The vast expertise of Nozag’s project manager showed to be very valuable. In addition, Nozag offered a service and a support that I have very rarely experienced. Nozag has largely contributed to find space for “everything” inside of the locomotive. Many thanks.»

Alexander Siegrist, Project Manager, Siegrist Elektroinstallationen & Controlling GmbH

Product / Detailed information

Worm gears combined with chain sprockets and precision roller chains are Nozag standard products. Often, a consultation meeting produces a solution based on our standard products range, which are then adapted and delivered ready for installation. We will be glad to support you at any time to engineer, calculate and optimize your drive solutions.

Shop

Shop

Any Questions?

Any Questions? Please call us

Please call us Products search

Products search

Shop

Shop